How Does LIMS Help?

AMIP can gather and build information through LIMS (Learning Integrated Manufacturing System) Devices.

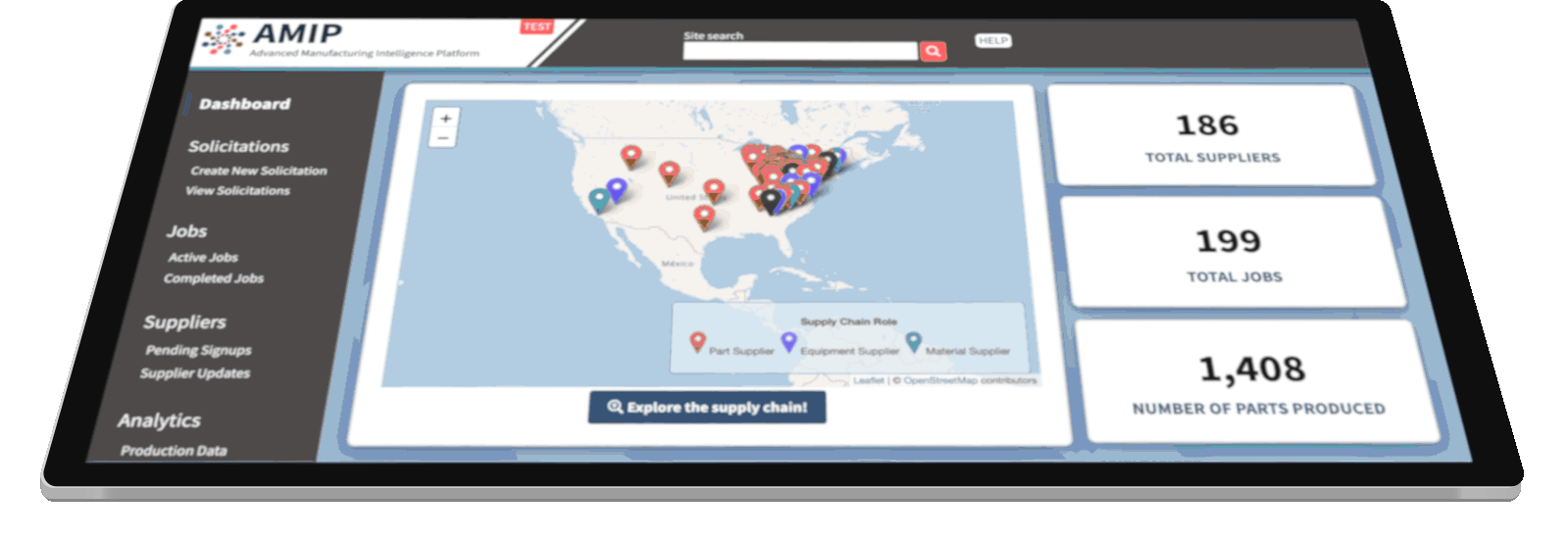

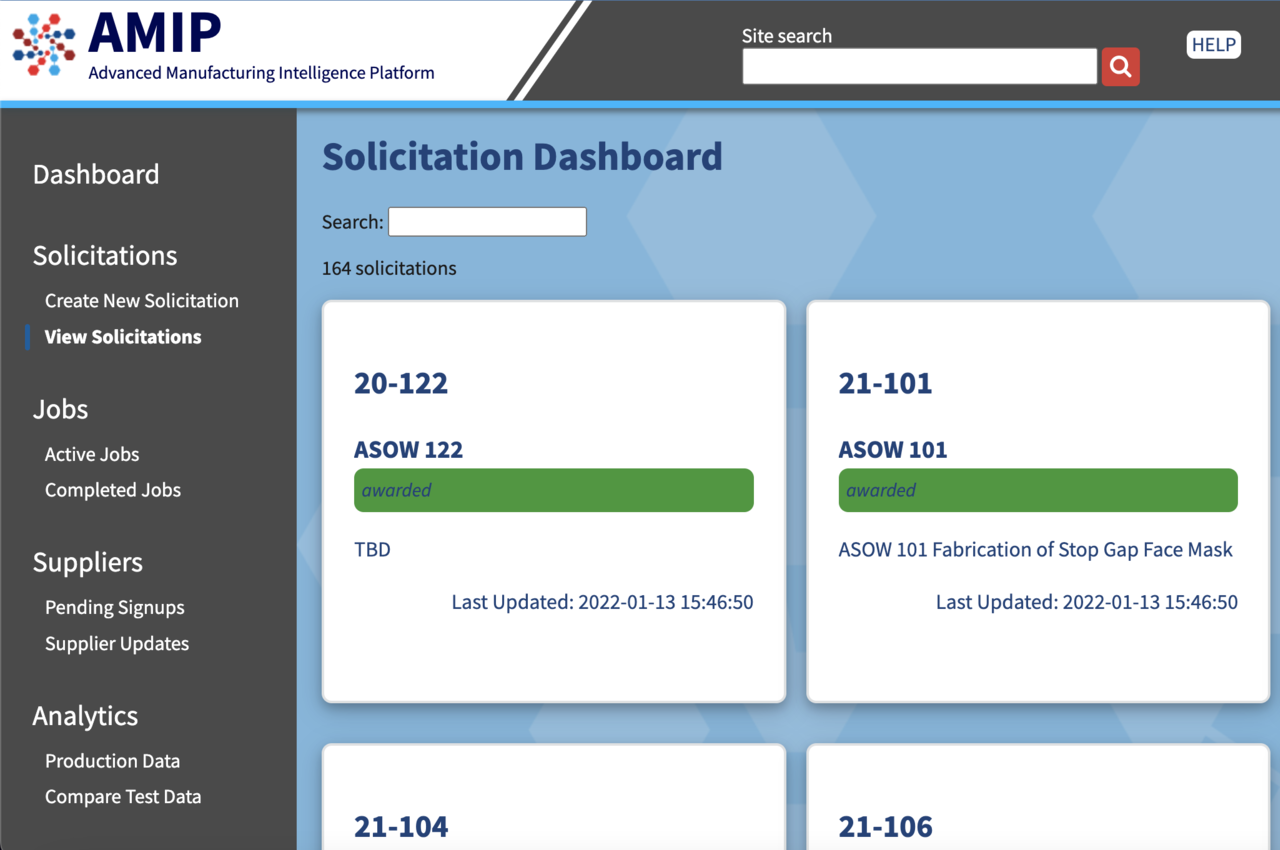

The AMIP system streamlines the procurement process, encouraging innovation, tracking build data, and analyzing data to determine best practices and processes.

Source through the supply chain

Monitor production processes

Ingest Build and Test Data for verification and analysis

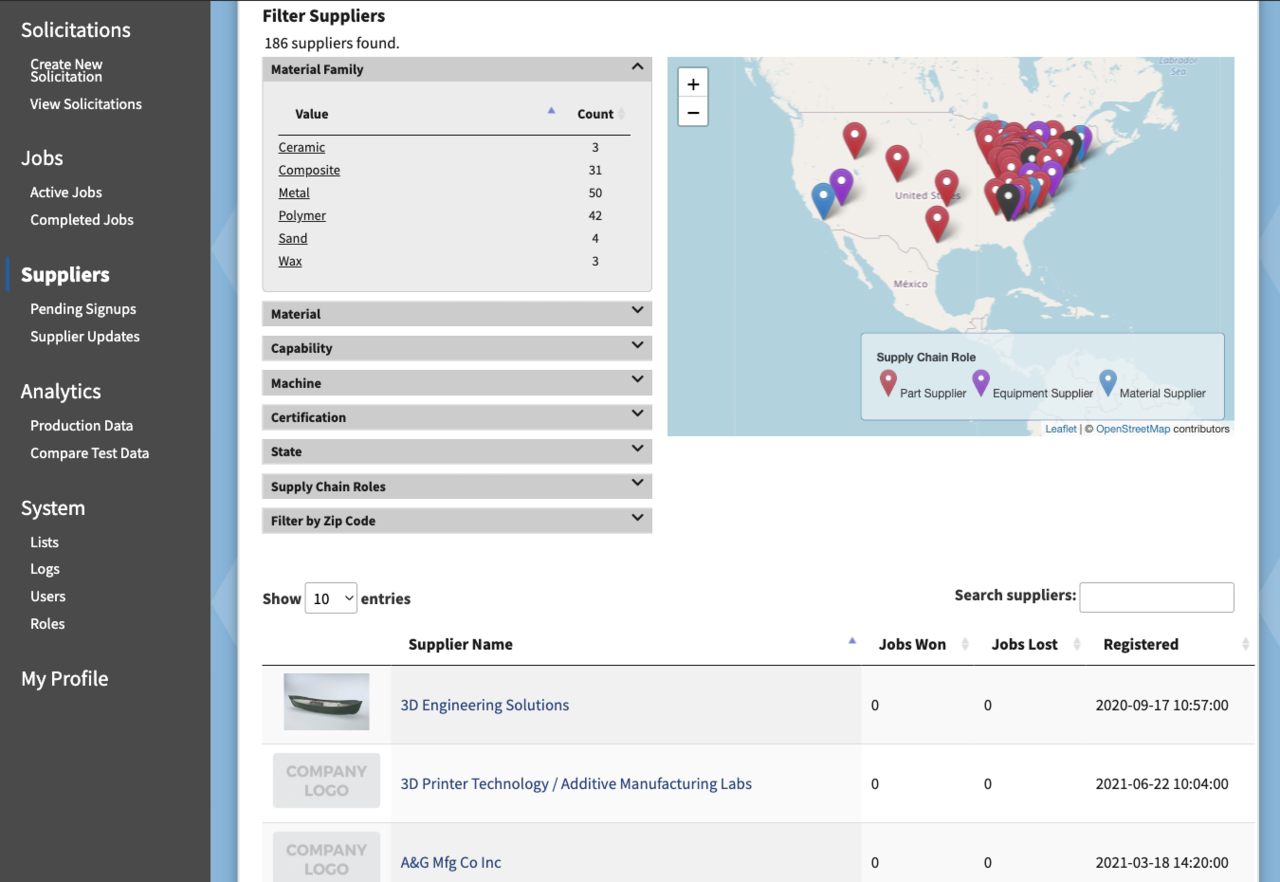

Search the Supplier database to identify Suppliers capable of meeting production needs.

Regional focus with national scale. Securely linking all regional supply chain participants.

Data collection of TDP, material, data, pre-build data and build data.

Ingest, store, analyze build and test data. Verify all data deliverables have been met prior to Part acceptance.

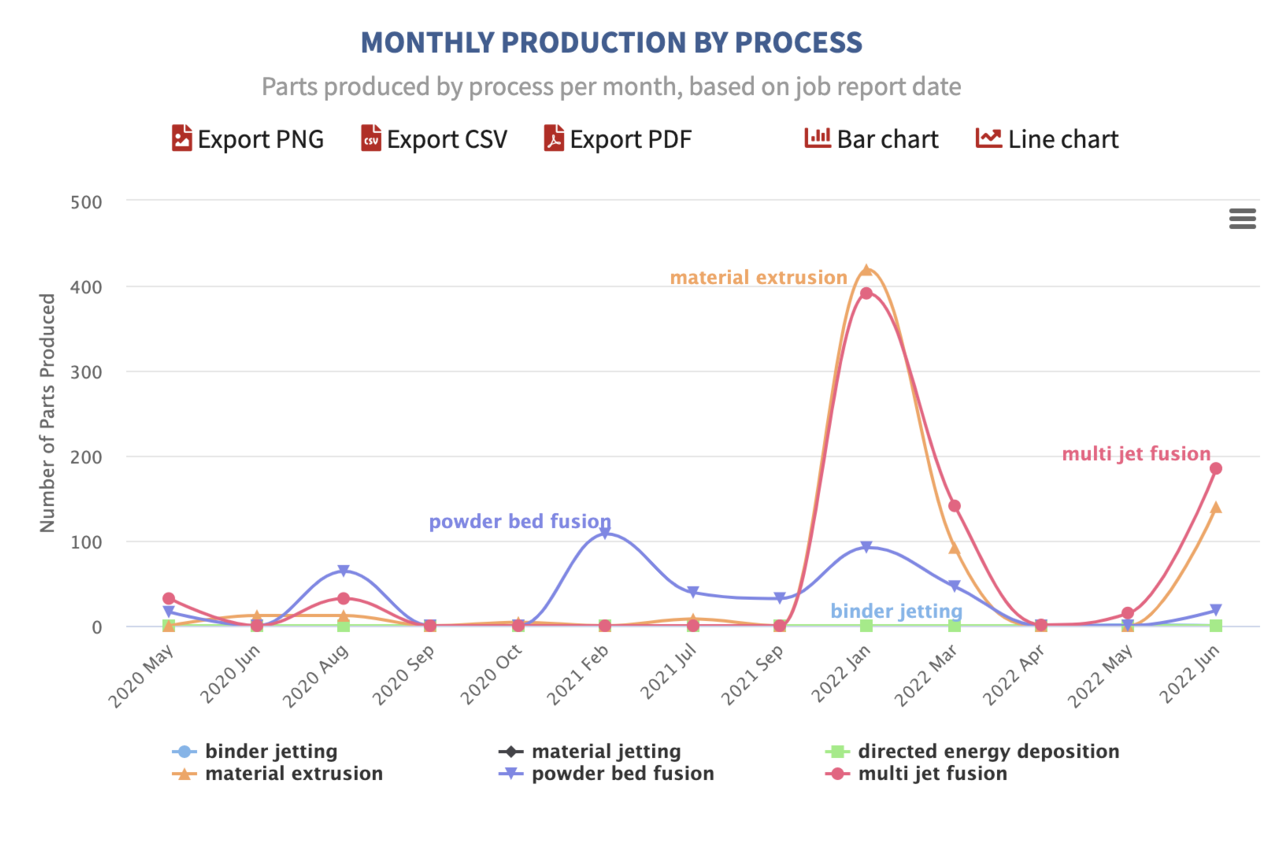

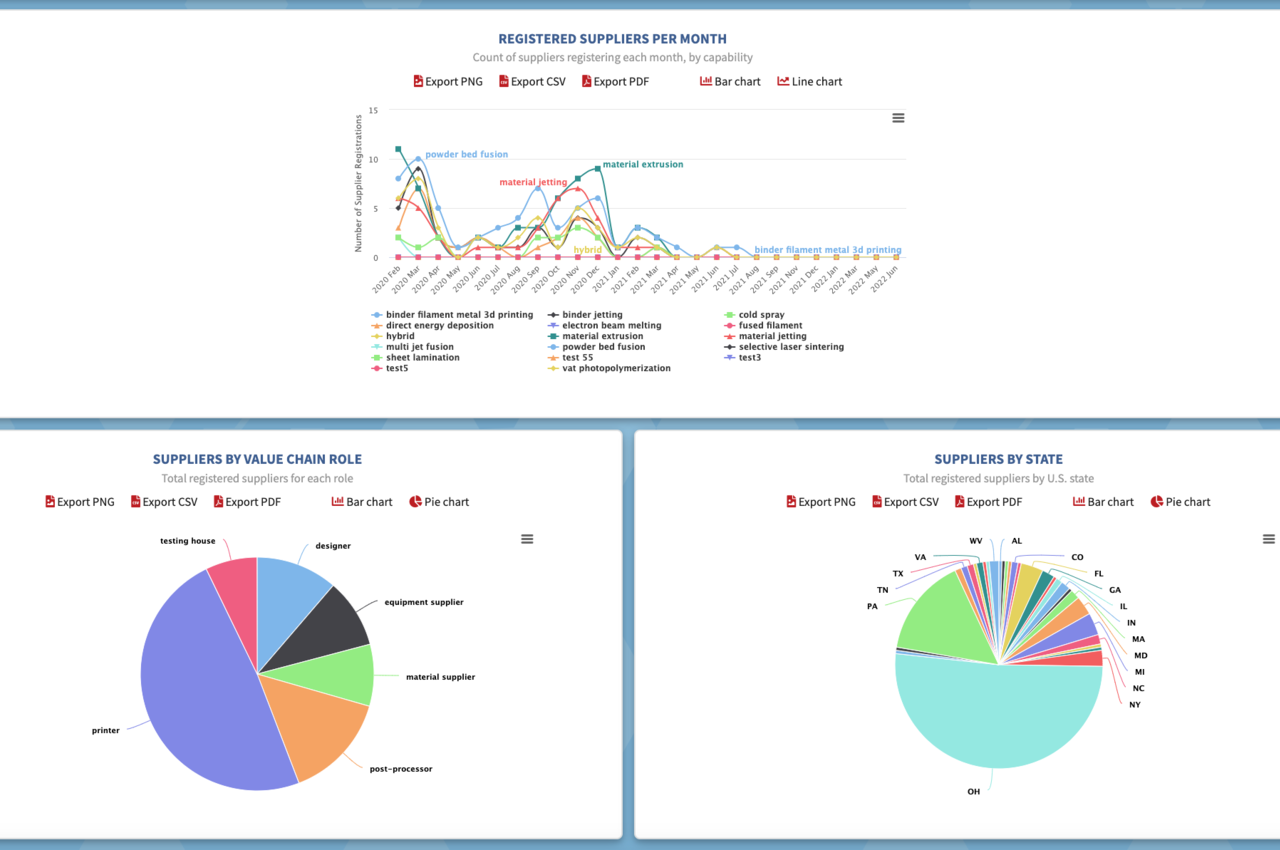

The Analytics page gives the user insight into the overall system metrics of number of suppliers, process types, materials used, and number of parts produced.

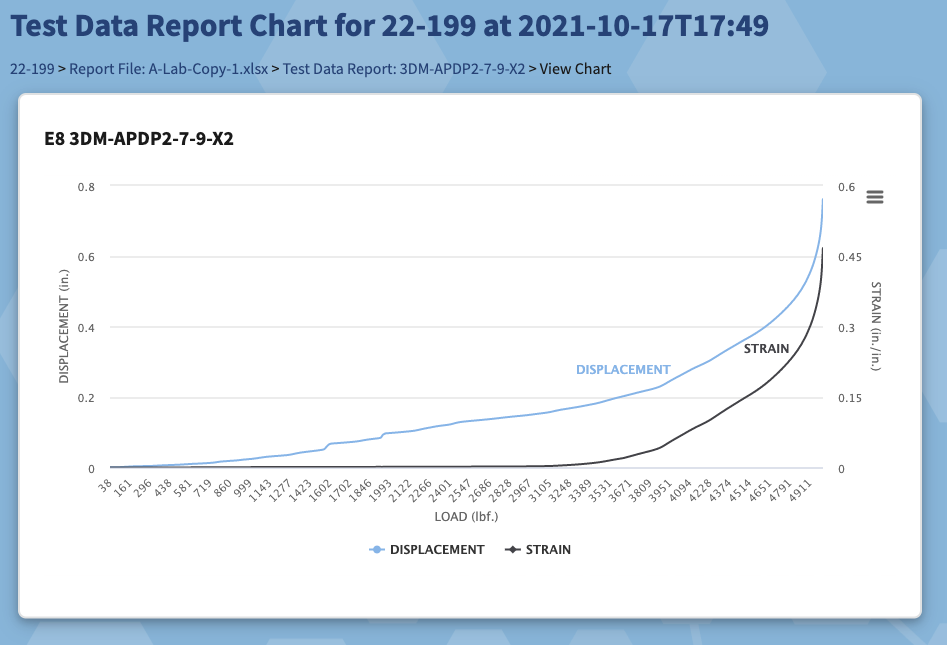

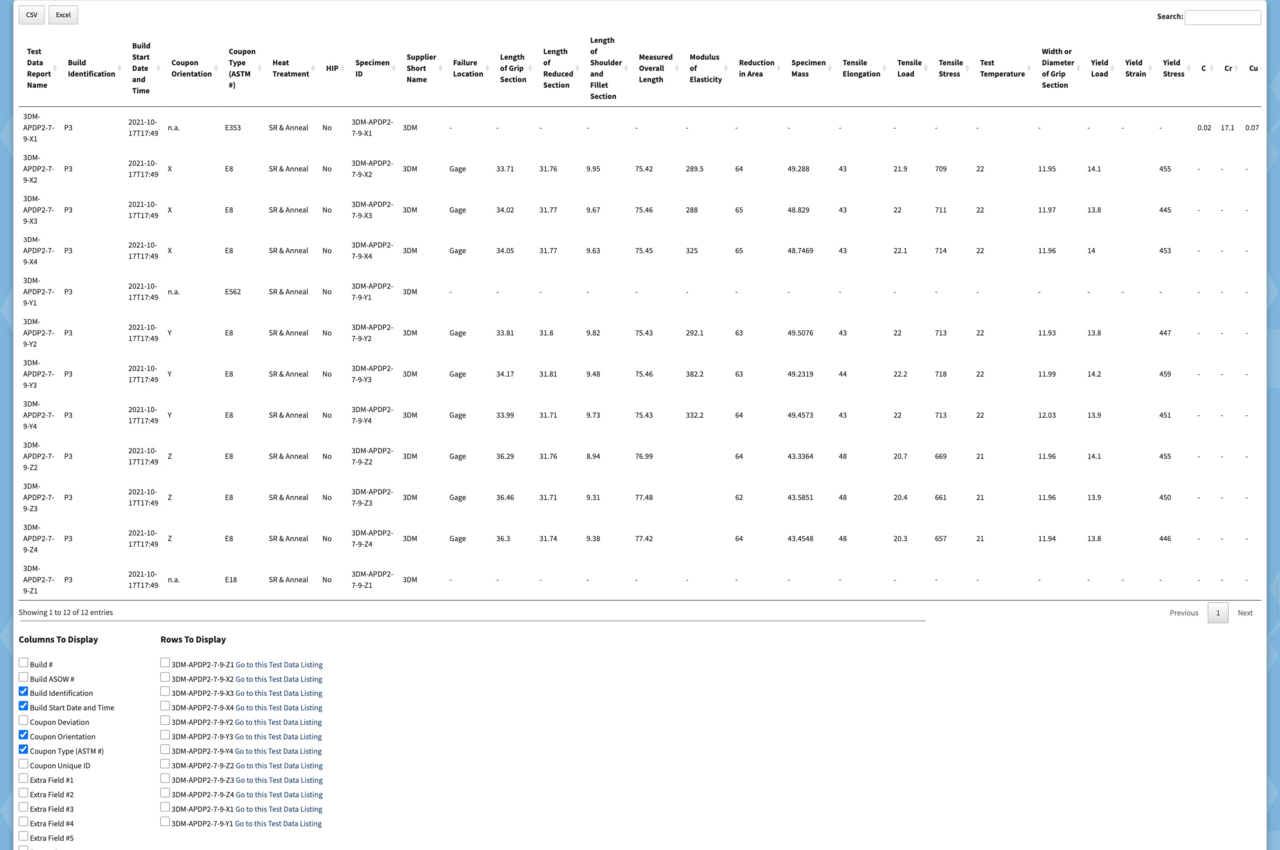

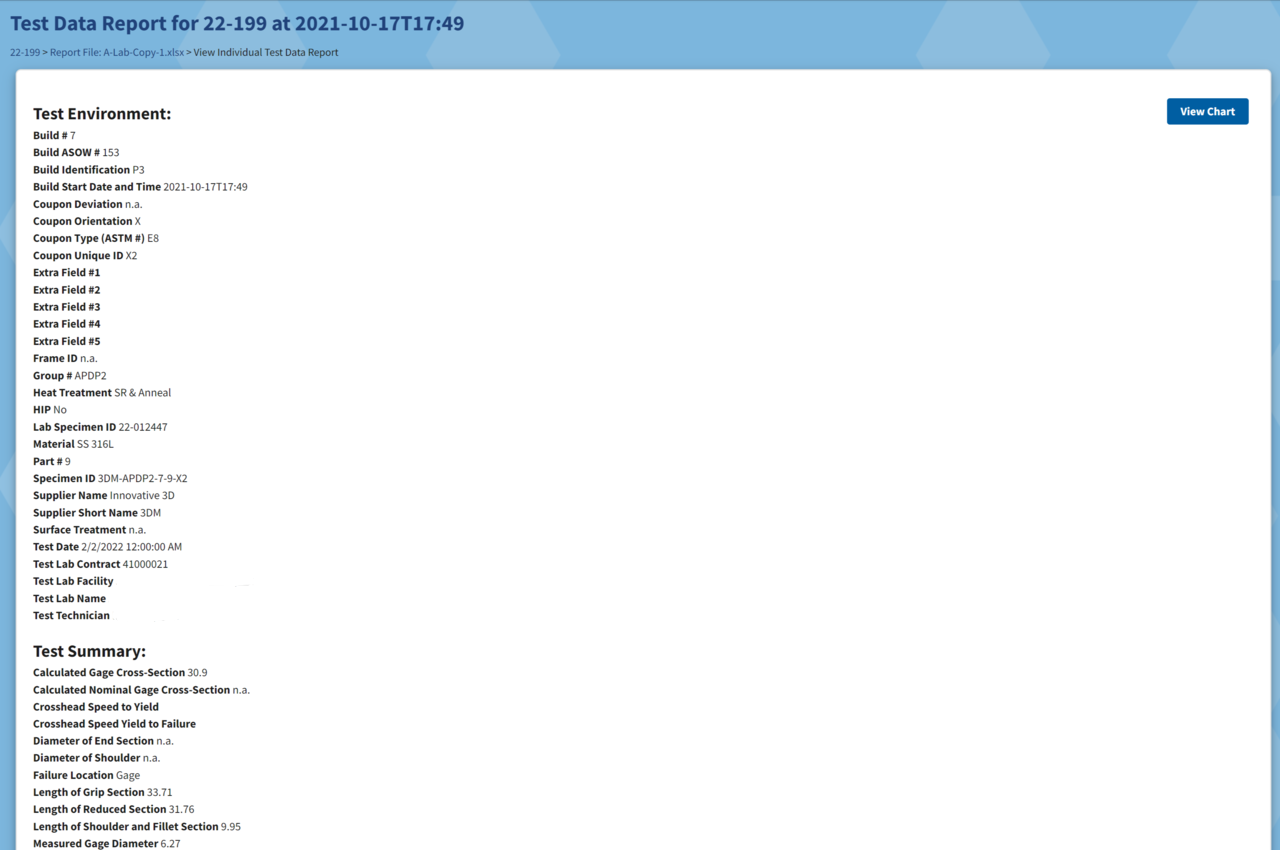

Test data can be collected from coupons for a build. The user can select tests from across Jobs, materials, build processes, ASTM Test Types; to visualize tabular data, and charted data from the ingested Test data. This can be used to identify best practices when selecting a material/build process for a specific part, and verify part quality.

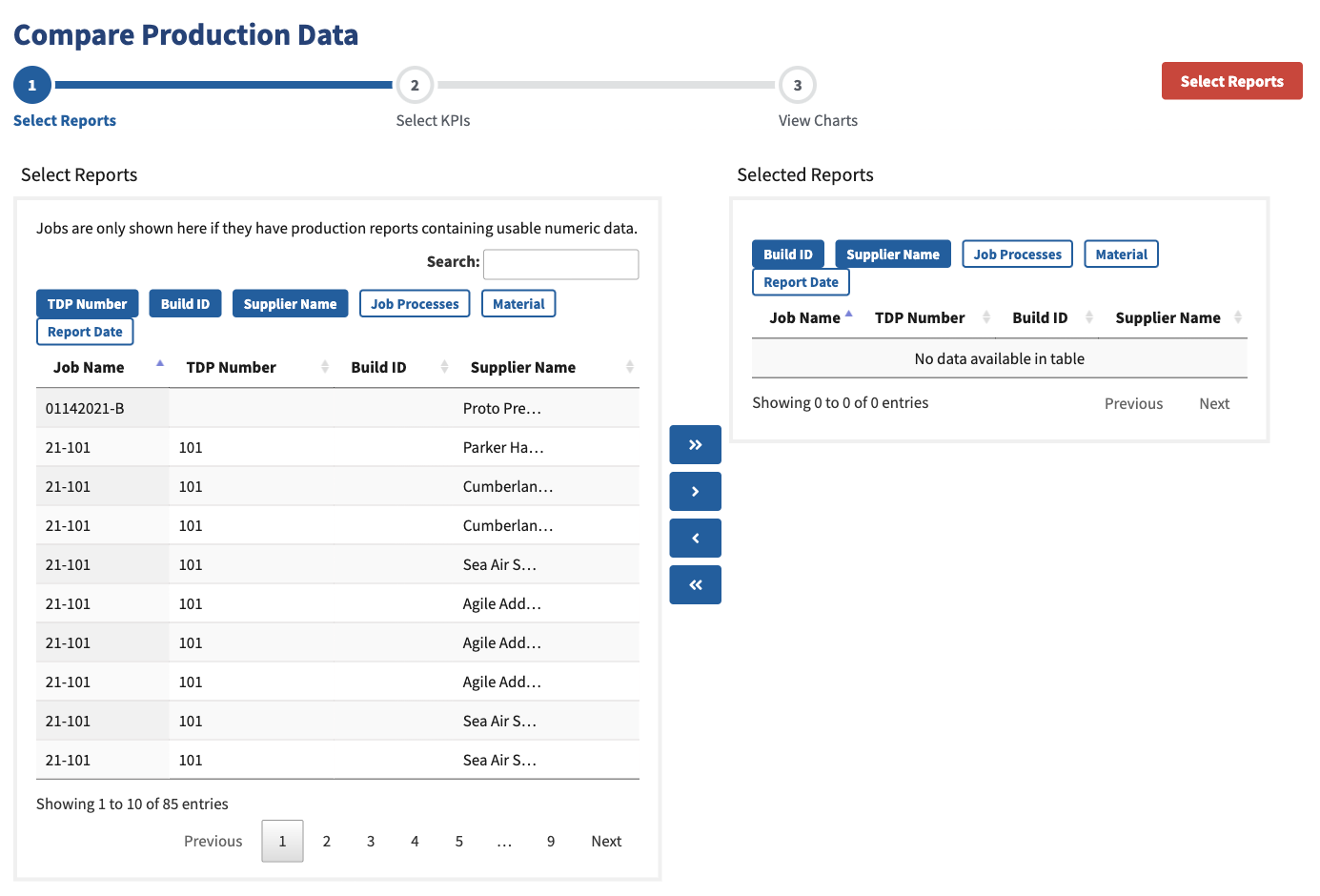

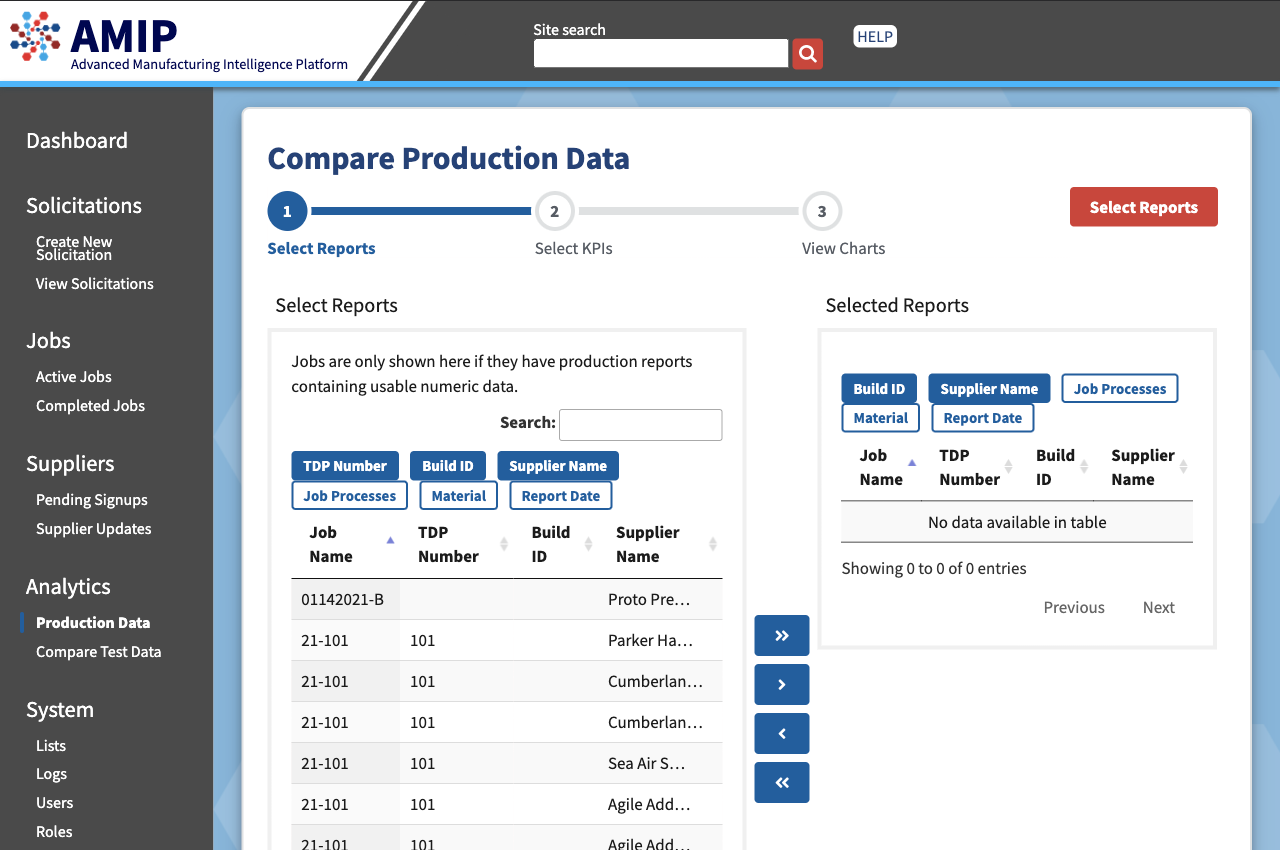

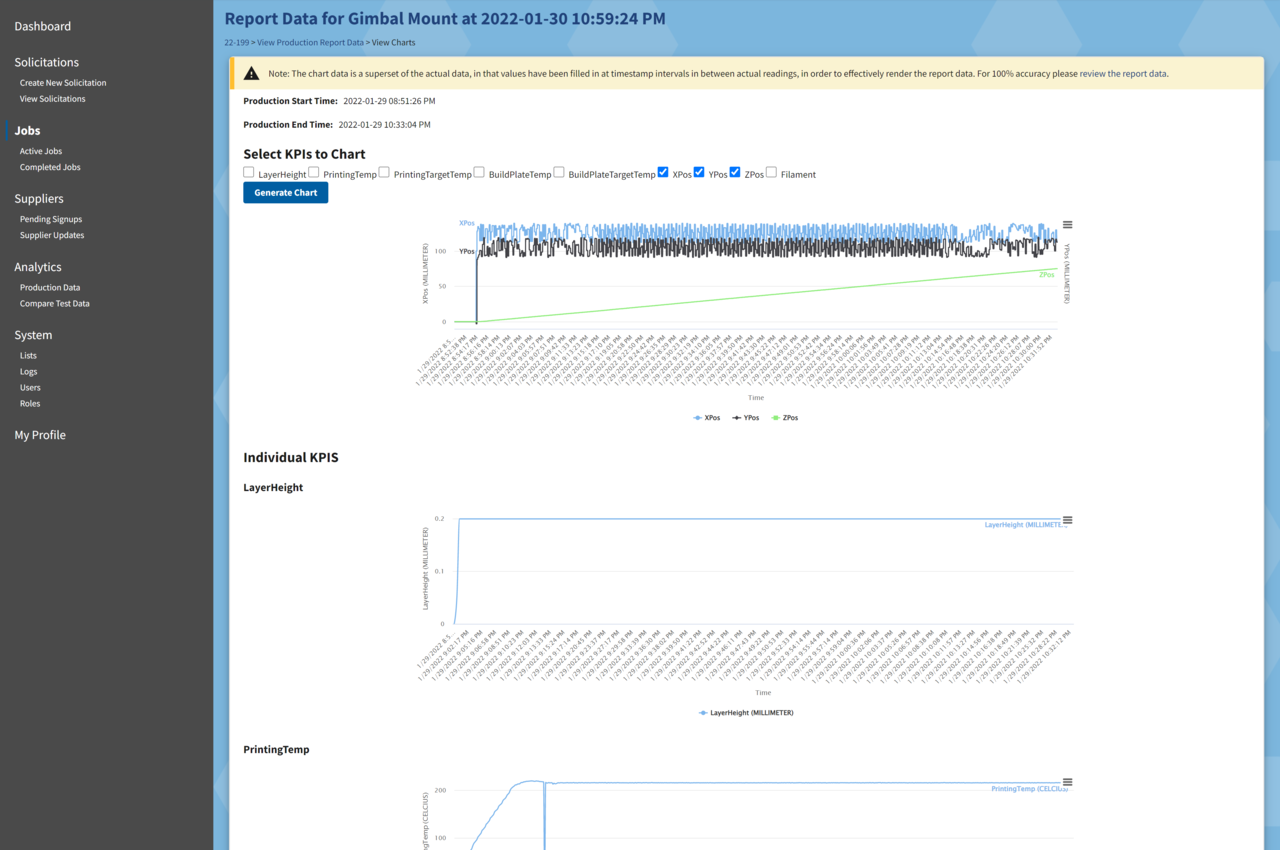

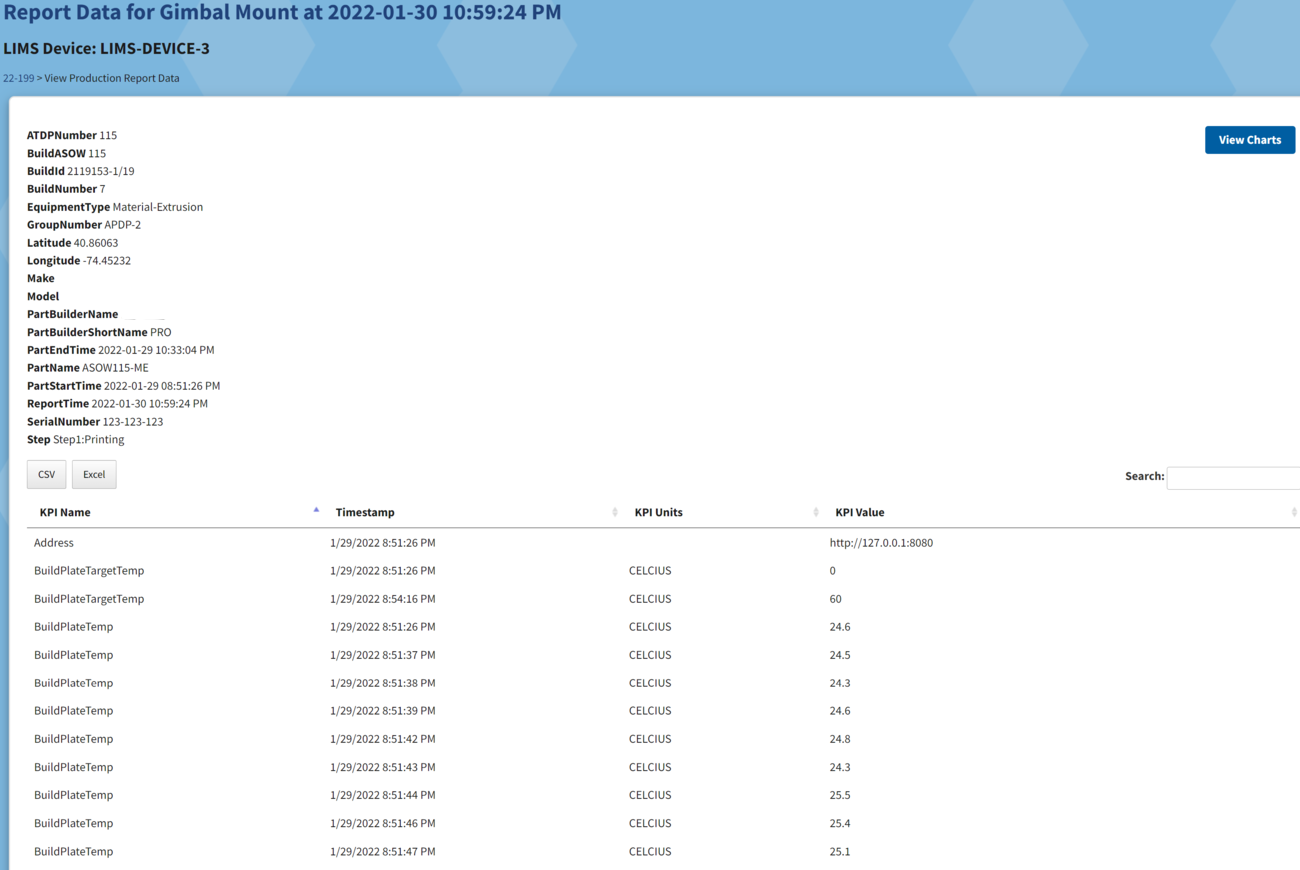

Production build data can be selected from across jobs, build processes, and materials; to visualize both tabular and charted data. This can be used to identify best practices when selecting a material/build process for a specific part, and verify part quality. Isolate a printer issue, monitor build quality, or meta data analysis..

Compliance is a moving target, we are constantly updating the code to address changes in STIG requirements

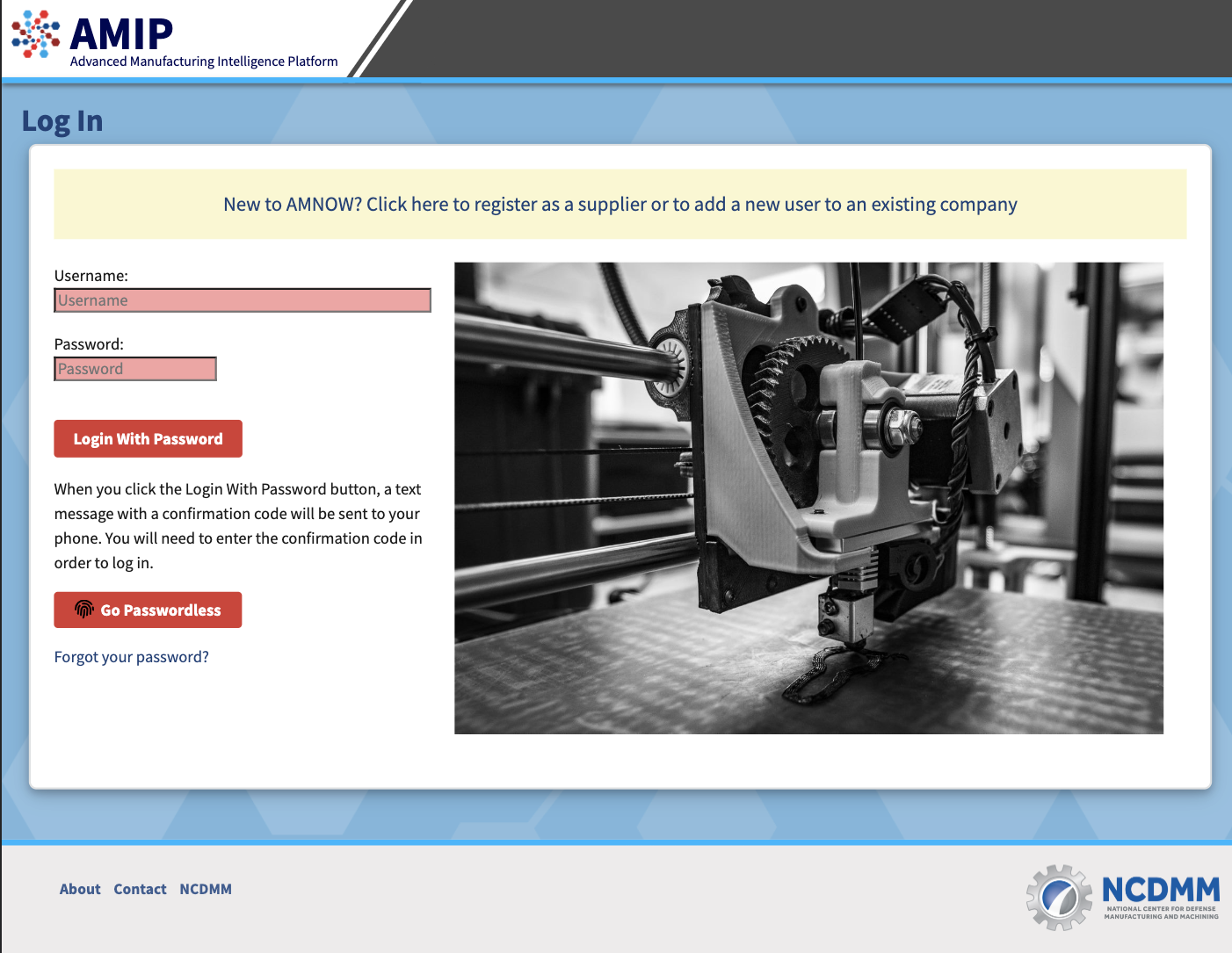

Secured authentication including CAC, MFA, and FIDO. Role-based authorization enforced.

Encryption of all Servers and Data at rest. AMIP is based in the Azure GovCloud and leverages all security features that environment provides. AMIP sits behind a firewall, and uses Azure Storage Service Encryption (256-bit AES) on both the App and Database servers. The Data-At-Rest has an additional layer of encryption using SQL Server encryption. All connections utilize TLS 1.3.

AMIP can gather and build information through LIMS (Learning Integrated Manufacturing System) Devices.

AMIP supports open source data ingestion and the system can handle data inputs from any source. AMIP partners with Lecs Energy who can supply a LIMS box on if desired. However, data can be captured by any method and loaded into AMIP.

Additive Manufacturing technology is a force multiplier for the supply chain. AMIP enhances the additive manufacturing process, identifies supply chain capabilities, and centralizes data analysis.